Case Study | The effects of grease, fat & oil

We hope this case study will help to understand the effects of grease, fat & oil on your private sewage system, drainage field and the environment. This example is of a Klargester Biodisc that has a wheel as part of the mechanism.

Observations & Findings

RE: site visit:- As per my visit, I arrived at the Treatment Plant at 830am with my colleague with a jetting machine to empty the holding tank (the settlement tank), which is the first chamber in the system, and to break up the encrusted white substance in the tank, as per our previous recommendations.

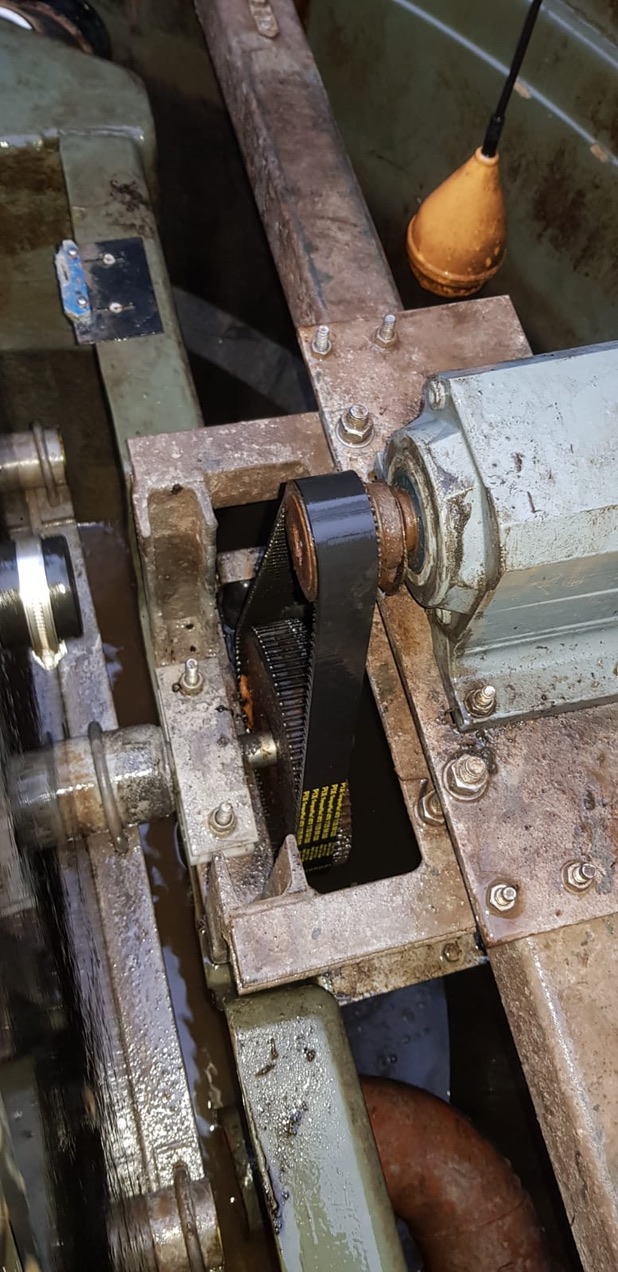

We opened the lid of the tank and found it in a dreadful state. The fatty type substance was so thick, it had restricted the wheel from turning and had broken the belt, stopping the treatment, stopping the large wheel. We inserted our 3-inch suction hose into the fatty layer; the heavy strange material, which was very thick, approximately 400mm in depth floating on top of the sewage mixture, including the black substance. The wheel had stopped turning and the treatment area was filled with grease, fat and the unknown substance was also in the last chamber, which is normally the clean water, we, therefore, had to empty the whole treatment plant.

We called in the electrical engineer who confirmed the belt broke due to the pressure of the semi solidified fatty substance on the bottom of the wheel. He tested the electrics, emptied, cleaned, and freed the wheel, reset the system, and started the Treatment Plant once again.

Due to prior denial of the situation and lack of responsibility from the site regarding the substances present in the tank, we asked where this large quantity of fatty substance was coming from.

The tenant denied knowledge of its origin as there are grease traps everywhere. The tenant was able to witness the severity of the problem first hand and the strain it was placed on the treatment plant, as well as confirm that the origin must be from the site as the substance was present immediately upon accessing the treatment plant.

There appeared to be some white fat substance stuck to the bottom of the last chamber, which is the chamber meant for clean water after its been through the treatment process. The tenant was quick to notice me pointing this out to my colleague and rushed across as we were trying to remove it. The tenant immediately pointed to a small bush, it would appear, someone had removed from the garden with the top cut off, with only a stem-roots attached, and insisted that this was the cause of the problem. I explained to him it was far too low in the tank to cause a problem, however, I asked my colleague to get his equipment and we removed the abandoned stump and roots from the bottom of the tank. This turned out to be, as suspected, a small bush with the top cut off that someone had thrown in.

Despite witnessing the appalling state of the treatment plant and the amount of work and effort required to empty it on this occasion, the tenant questioned as to when the turf could be put back on the drainage field. I tried to explain to him that the treatment plant must be dependable, working, and only dealing with domestic sewage (not the extra substances present) before reinstating the drainage field, however, he seemed wholly uninterested.

Initially, upon lifting the lid of the treatment plant, we asked the tenant to bring his wife, to see the extent of the problem. However, we were told The wife was unavailable due to dealing with business matters, so we asked the tenant to inform the owner of the property as to what has witnessed.

The owner of the property is aware of the situation, asking what can we do, to protect the Treatment Plant and, most importantly, can I guarantee the land drains. I explained that I have been trying to protect the treatment plant, especially the land drains since the tenants moved in, however nothing I’ve said has been listened to. The substances present in the tank neither floats nor sinks, which is unsuitable for a treatment plant, and continues to be present no matter what I do and no matter what I say to the tenants.

I have been insisting continually since the tenants moved in that we must stop the fatty substance entering the treatment system,

Please note, the substance being pumped into the land drains is causing pollution. The fatty substance is filling the tank unnecessarily causing disruption with treatment, breakdowns of mechanical components.

Therefore, in the current circumstances, the only way I can guarantee anything with regards to the land drains is to stop the treatment plant discharging. Although I’m afraid if we stop the discharge to the land drains, I believe the quantity of the contaminated water (containing very little sewage) from the new tenants, from the kitchen and the main house, would overflow possibly within 2 to 4 days, flooding the lowest part of the system and the area near the kitchen (the new kitchen). The sewage, oil, and fatty substances will overflow above ground.

Please note: The Treatment Plant has been damaged. I have replaced the electric motor and gearbox only six or seven weeks after the tenants moved in. I’ve also noticed that the barrier is starting to leak at the bottom, possibly because of fatigue, and I fear it may get worse. I believe it’s not causing a problem at the moment as it is at the bottom of the barrier.

Recommendation

To protect the treatment plant from further damage and in an attempt to protect the land drains from pollution is as per previous recommendations; to empty the tank every 3 to 4 weeks, which will be enough to protect the Treatment Plant, but it will not protect it from fatigue. In fact, fatigue will increase, and it will not protect the land rains from pollution. To guarantee the land drains from pollution, my recommendation is to stop the discharge and empty the whole tank as you would a cesspit (containment only). In order to stop it from overflowing, we will need to empty in the first instance, every 2 to 3 days, especially after removing the two pumps or fitting a fine filter to the outlet dip pipe. This will need to continue until the threat of pollution is removed, i.e. the strange material which could be grease or semi solidified fat, and the black substance is stopped from being allowed to go into the tank.

According to the binding rules, the owners of the property are known as the 'operator' and are therefore responsible for the correct operation of the system using Asl and any pollution it may be causing. Any sign or suspicion of pollution must be stopped immediately. The owner of the property can order no discharge and give instruction to remove the pumps. There will also need to be a plan and implementation of an emptying schedule that would guarantee no pollution, as we don’t seem to have any cooperation from site and have restricted or no access to assess the origin of the issues.

If the system is left to get out of control and the pollution is not able to be stopped, the Environment Agency (EA) will need to assess the situation. The EA may issue a prohibition order (no discharge; to cap off the system). If the system is found to be discharging after the prohibition order has been issued, the EA would more than likely issue fines and remove the right to discharge because the system is not meeting the binding rules in more ways than one.

By emptying every three days, we will be able to measure the volume of wastewater the tenants are using daily. The accepted rough calculation for each person is 150 liters per day, according to British Water’s flows and loads.

In accordance with the general binding rules, in order to discharge to the ground, you must use a septic tank or a small sewage treatment plant and a drainage field (infiltration system). You must apply for a permit if you release (‘discharge’) more than 2 cubic meters (2,000 liters) per day into drainage fields / land drains. We, therefore, need to determine the current usage and discharge volume. Emptying every five days could possibly be under 10,000 liters, however until we find out how long it takes the main house and the large professional kitchen to fill the tank, we will need to attend every three days and if it is full when we arrive, we will need to increase our visits to every two days (in order stop pollution occurring to the land drains). If the tank is not full then we can lengthen the emptying to every four to six days or more if there is no risk of pollution

Since you have allowed for us to attend site every three days, and now every seven days (since we fitted the filter), on each occasion, we have emptied the tank over the very short 2-3, or 7-day periods. We have taken a photo of the thin layer of fat (white) found to be present, and approximately 10mm to 15mm thick.

Can the tenants stop putting the fat or fatty stuff down the drains leading into the Treatment Plant. As you are aware, fats, grease, and oil are not allowed in sewage treatment plants, especially in such vast quantities.

If you multiply the 10mm thick fat layer over the short three-day period, by previous emptying periods of up to 8 weeks, it’s easy to understand that the amount of fatty black material had accumulated, and quite often measured over 400mm thick, encompassing the top of the tank, jamming the wheel. Thus, causing the treatment plant to completely fail on two occasions. As stated in prior reports, the treatment process was often overwhelmed.

Please note, the treatment of the actual human waste ‘sewerage’, was being treated easily within the Treatment Plant, I.e. the bacteria eating the separated sewage water clean before it got halfway to the end of the wheel.

Proof of pollution is on the filter we fitted. Small particles of fat are finding their way onto the filter. In the past, this would be pumped up to the land drains.

Conclusion

After the emergency breakdown

ASL immediately emptied down the tank on an emergency basis, washed down the tank with the high-pressure jetting machine, thoroughly cleaned, carried out an inspection and service, re-adjusting bearings, supplied and installed a motor and gearbox, new drive belt, etc and the treatment plant was up and running the same day. Klargester / Kingspan have confirmed that they would not cover the new motor under warranty due to the fat present in the system.